TRANSPARENCIES ELECTROHYDRAULICS FESTO

64 Pages • 3,669 Words • PDF • 7.6 MB

Uploaded at 2021-09-24 08:24

This document was submitted by our user and they confirm that they have the consent to share it. Assuming that you are writer or own the copyright of this document, report to us by using this DMCA report button.

Fundamentals of Electrohydraulics Collection of Transparencies

a

b a

a

T

A

P

B

T

A

P

B

A

B

P

T

b

b

095051 GB

Order no.: Designation: Description: Edition: Author: Graphics: Layout:

095051 E.-HYDR-FOLIEN. D:OT-TP601-GB 07/2001 Dieter Scholz Doris Schwarzenberger 18.07.2001, Beatrice Huber

© Festo Didactic GmbH & Co., D-73770 Denkendorf, 2001 Internet: www.festo.com/didactic e-mail: [email protected] The copying, distribution and utilization of this document as well as the communication of its contents to others without expressed authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved, in particular the right to carry out patent, utility model or ornamental design registration.

Foreword

This set of overhead transparencies has been designed for use with the basic level of the technology package TP600 “Electrohydraulics”. The set of overhead transparencies and the technology package form part of the Learning System for Automation from Festo Didactic GmbH & Co. The 30 transparencies in this set have been optimised from the didactic and methodological points of view. Each transparency is accompanied by a short text which provides the trainer with a quick overview of the training contents of the transparency concerned. Training contents

· · · ·

Basic principles of electrohydraulics Function and use of electrohydraulic components Basic principles of electrical engineering Production and interpretation of standard hydraulic and electrical circuit diagrams

The text sheet includes a complete illustration of the transparency, in certain cases with additional explanations and legends which the trainer can enter on the transparency in the course of a training session. The advantages of this concept are: · The trainer can add to the transparencies step by step in the course of a training session. · The trainer is thus able to create a lively and interesting atmosphere. · The provision of accompanying text means less preparation work for the trainer. New! Electronic presentation

The enclosed CD-ROM contains the entire overhead transparencies and accompanying text of this edition in an electronically presentable form in the files „Electrohydraulics _transparencies.pdf“ and „Electrohydraulics _text.pdf“. In addition to the screen presentation, which can be made in any order, the contents can be printed out and text and graphics can be used for your own training ® ® preparations, insofar as the functionality of the required Adobe Acrobat Reader permits this. This freely distributable software is available on the CD-ROM in the currently valid English version for Windows 95/98/NT for installation in the directory „Acrobat_Reader“. Please start the file „rs405eng.exe“ and follow the subsequent dialogue.

© Festo Didactic GmbH & Co. • Electrohydraulics

Contents

Electrohydraulic press _______________________________________ Transparency 1 Schematic layout of an electrohydraulic installation ______________ Transparency 2 Electrical power supply unit __________________________________ Transparency 3 Electrical circuit ____________________________________________ Transparency 4 Measuring circuits __________________________________________ Transparency 5 Ohm’s law _________________________________________________ Transparency 6 Rectifiers __________________________________________________ Transparency 7 Analogue, digital and binary __________________________________ Transparency 8 Momentary and sustained contact switches _____________________ Transparency 9 N/O, N/C and changeover contacts ___________________________ Transparency 10 Limit switches _____________________________________________ Transparency 11 Proximity switches _________________________________________ Transparency 12 Solenoid (electromagnet) ___________________________________ Transparency 13 Electrohydraulic converters (solenoid valves)___________________ Transparency 14 Dry solenoids – wet solenoids________________________________ Transparency 15 Solenoid valve connections__________________________________ Transparency 16 Relays and contactors ______________________________________ Transparency 17 Direct activation – indirect activation __________________________ Transparency 18 Signal inversion ___________________________________________ Transparency 19 Latching__________________________________________________ Transparency 20 Circuit diagram ____________________________________________ Transparency 21 Hydraulic power pack_______________________________________ Transparency 22 Hydraulic circuit ___________________________________________ Transparency 23 Electrical power – hydraulic power ____________________________ Transparency 24 Power losses______________________________________________ Transparency 25 Pressure switches__________________________________________ Transparency 26 4/3-way solenoid valve _____________________________________ Transparency 27 4/3-way solenoid valve, piloted ______________________________ Transparency 28 Electrical safety____________________________________________ Transparency 29 Hydraulic safety ___________________________________________ Transparency 30

© Festo Didactic GmbH & Co. • Electrohydraulics

1

Electrohydraulic press Function units

· · · ·

Motor with hydraulic pump Control panel Valve manifold Cylinder

The hydraulic press is controlled via the electrical control panel. Electrical signals are used to activate the valves in the hydraulic installation. The electrohydraulic press is used to form rectangular troughs.

Motor with hydraulic pump Valve manifold

Actuator (cylinder)

Control pane

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrohydraulic press

© Festo Didactic GmbH & Co.

TP 601, Transparency 01

2

Schematic layout of an electrohydraulic installation Division of installation into signal control section and hydraulic power section. Signal control section

Input and processing of electrical signals. Solenoid valves form the interface between the electrical signal control section and the hydraulic power section. Controls the flow of hydraulic fluid by means of solenoid valves. Actuators convert hydraulic energy into motions.

Power section Signal control section

Hydraulic cylinder

Signal processing

Signal input

è

Solenoid valve

è

è

è è Power supply

è

Hydraulic power section

Hydraulic power supply (conversion)

© Festo Didactic GmbH & Co. • Electrohydraulics

Schematic layout of an electrohydraulic installation Power section Signal control section

è

è

è

è

è

è

© Festo Didactic GmbH & Co.

TP 601, Transparency 02

3

Electrical power supply unit Connection to mains supply. Supplies signal control section with specified or maximum voltage and current values. Functions in power supply unit

· · · · ·

Voltage transformation Rectification Smoothing Stabilisation Fuse protection

In mobile hydraulic systems, rechargeable battery systems or generators are used as a power supply for the signal control section.

230V AC DC 24V

50 °C

TR

G

Transformer

Rectifier

C

T

T

Smoothing Stabilisation

Fuse

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical power supply unit 230V AC DC 24V

TR © Festo Didactic GmbH & Co.

G

C

T

T TP 601, Transparency 03

4

Electrical circuit A circuit consists of at least a power source, a load device and connecting lines. Electrical current will flow only in a closed circuit. Technical direction of current flow

Electrical current flows from the positive terminal of the power supply to the negative terminal.

Figure A

Closed circuit without power supply.

Figure B

Introduction of a power supply to complete the circuit.

A

B

+

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical circuit A

© Festo Didactic GmbH & Co.

B

TP 601, Transparency 04

5

Measuring circuits Voltage measurement

The voltage drop across a load device is measured in parallel with the device.

Current measurement

Electrical current is measured in series.

+

+

Voltage measurement

Current measurement

© Festo Didactic GmbH & Co. • Electrohydraulics

Measuring circuits

+

+

-

-

© Festo Didactic GmbH & Co.

TP 601, Transparency 05

6

Ohm’s law Ohm’s law

Describes the relationship between current (I), voltage (V) and resistance (R). With ohmic resistances, the current rises in linear proportion to the voltage. The value pairs for a constant resistance lie on a straight line. The current I is proportional to the voltage V. Mathematical formula for Ohm’s law:

V=R•I

I=

+

V=R•I I=V:R

Resistance R

Voltage V 10 V 20 V

30 V

40 V

Relay

0.5 A

1.5 A

2.0 A

Solenoid coil

0.33 A 0.66 A 1.0 A

V R

1.33 A

2.0 A 1.5

A R

1.0 A

1.0

V

I

Graph

0.5 0

0

10

20

30 V 40

V

© Festo Didactic GmbH & Co. • Electrohydraulics

Ohm’s law Voltage V 10 V 20 V

Resistance R

30 V

40 V

Relay Solenoid coil

-

A

R

V

1.0

I

+

2.0 A 1.5

0.5 0

0

10

20

30 V 40

V © Festo Didactic GmbH & Co.

TP 601, Transparency 06

7

Rectifiers Rectifiers convert AC to DC. Diodes are conductive in only one direction. The polarity of the negative half-wave of the alternating voltage is reversed. The pulsating voltage is smoothed using a capacitor and filters (reactance coil, resistor).

L

~ C

Diodes

t

=

V

Voltage smoothing

V

V

Voltage retification

R

t

t

© Festo Didactic GmbH & Co. • Electrohydraulics

Rectifiers ~

t © Festo Didactic GmbH & Co.

V

V

V

=

t

t TP 601, Transparency 07

8

Analogue, digital and binary Analogue values

Analogue values describe continuous functions, such as the continuous filling of a bucket of water.

Digital values

Digital values describe integer parts of a maximum value. A dice, for example, shows one of six possible numbers.

Binary values

Binary values are a special form of digital values. They can assume only two values, such as in the case of a switch, which can only be on or off.

halffull empty

Filling time t

6 5 4 3 2 1 0

On 1

Light

full

Value

Volume V

+

Experiments with dice

Off 0

Switching time point

Time t

© Festo Didactic GmbH & Co. • Electrohydraulics

Analogue, digital and binary

+

Filling time t © Festo Didactic GmbH & Co.

Light

Value

Volume V

-

Experiments with dice

Time t TP 601, Transparency 08

9

Momentary and sustained contact switches Actuation of contacts. Momentary contact switch

A momentary contact switch has a “rest position” and an “actuated position”.

Sustained contact switch

A sustained contact switch has two detents. It thus has two rest positions. Momentary and sustained switches can close or open current paths or switch from one current path to another.

3

3

4

4

© Festo Didactic GmbH & Co. • Electrohydraulics

Momentary and sustained contact switches

© Festo Didactic GmbH & Co.

TP 601, Transparency 09

10

N/O, N/C and changeover contacts N/O

Contact normally open in rest position.

N/C

Example: Momentary-contact switch

Changeover contact

N/O and N/C contacts in a single housing; one contact is open while the other is closed. The designations of the switch contacts are governed by the European standard EN 50012.

Switch elements Connection (N/O contact)

3 4

1 2

2

4

Connection (N/C contact)

1

© Festo Didactic GmbH & Co. • Electrohydraulics

N/O, N/C and changeover contacts

© Festo Didactic GmbH & Co.

TP 601, Transparency 10

11

Limit switches Determining the position of a positioning slide. Electrical contacts are actuated when a defined intermediate or end position is reached. Limit switches can be connected up as N/O, N/C or changeover contacts.

Switch lever Stem (insulated)

Contact

Snap-action mechanism

© Festo Didactic GmbH & Co. • Electrohydraulics

Limit switches

© Festo Didactic GmbH & Co.

TP 601, Transparency 11

12

Proximity switches Inductive

Signal is generated by the presence of any material with good conductivity in an oscillating magnetic field.

Capacitive

Signal is also generated by all insulators with high dielectric constants in an electrical field.

Optical

Signal is generated when light barriers are interrupted or when light is reflected back to an optical sensor.

Reed switches

Signal is generated by magnets whose fields close the built-in contacts in the switch.

inductive

Metal

Reed switch

Magnet capacitive

Metal or Insulator

optical

reflective component

magnetic

© Festo Didactic GmbH & Co. • Electrohydraulics

Proximity switches

© Festo Didactic GmbH & Co.

TP 601, Transparency 12

13

Solenoid (electromagnet) A magnetic field with concentric field lines is created around a conductor carrying an electrical current. A coil carrying an electrical current develops a uniform magnetic field in its axial direction due to the overlapping of field lines. By appropriate alignment of elementary magnets, an iron core can be made into a switchable electromagnet.

Field around a conductor

Iron core

+

Coil Coil

© Festo Didactic GmbH & Co. • Electrohydraulics

Solenoid (electromagnet)

+ -

© Festo Didactic GmbH & Co.

TP 601, Transparency 13

14

Electrohydraulic converters (solenoid valves) Convert electrical signals into hydraulic switching operations. The switching armature is drawn into the coil, which acts as a magnet. This produces a displacement of the actuating piston in the hydraulic 4/2-way valve.

Switching armature

A

B

P

T

4/2-way solenoid valve

T

A

P

B

L

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrohydraulic converters (solenoid valves)

© Festo Didactic GmbH & Co.

A

B

P

T

TP 601, Transparency 14

15

Dry solenoids – wet solenoids Dry solenoid

The solenoid is separated from the hydraulic fluid; a seal is required on the stem.

Advantage

· Simple construction

Wet solenoid

The armature chamber of the solenoid is filled with hydraulic fluid, the solenoid operates in oil.

Advantages

· · · ·

Low friction Little abrasion Good heat dissipation Long service life

seal

Dry solenoid

Wet solenoid

© Festo Didactic GmbH & Co. • Electrohydraulics

Dry solenoid

© Festo Didactic GmbH & Co.

Wet solenoid

TP 601, Transparency 15

16

Solenoid valve connections Connector components

· Solenoid with plug base · Cable with connector socket Electrical signals are transmitted via standard connectors.

Advantages

· Reliable alignment of connections · Connections can be attached and detached quickly · Protected against dust and water

2 3 1

Electrical connections

Protective earth connection Plug base

© Festo Didactic GmbH & Co. • Electrohydraulics

Solenoid valve connections 2 3 1

© Festo Didactic GmbH & Co.

TP 601, Transparency 16

17

Relays and contactors Definition

Switches which are actuated and held in their actuated positions electromagnetically. Used to separate control and power circuits.

Special feature of relays

· · · ·

Special feature of contactors

Each main contact is of double-break type (contacts used as main contacts), suitable for · all power ratings from small to very large · only N/O and N/C contacts

Hinged-armature design Single-break contacts Used for logic gating of signals (generally) changeover contacts

Coil

Iron core Armature

Return spring Contacts

+ +

Contacts Return spring Hinged-armature solenoid

Coil Plunger-armature solenoid

© Festo Didactic GmbH & Co. • Electrohydraulics

Relays and contactors

+ -

+ -

© Festo Didactic GmbH & Co.

TP 601, Transparency 17

18

Direct activation – indirect activation Direct activation

Connection of a solenoid valve via a switch (Fig. A).

Indirect activation

Connection of a solenoid valve via a relay (Fig. B).

Advantage of indirect activation

· Separation of control and power circuits · The current passing through switch S1 (Fig. B) is lower, and the service life of the switch is significantly greater.

A

B

1

24 V

S1

3

S1

4

Y1 0V

1

24 V

K1

2

3 4

K1

3 4

Y1

0V

© Festo Didactic GmbH & Co. • Electrohydraulics

Direct activation

24 V

0V

© Festo Didactic GmbH & Co.

1

Indirect activation

24 V

1

2

0V

TP 601, Transparency 18

19

Signal inversion The output signal is inversely proportional to the input signal. Figure A

Signal inversion at relay K1.

Figure B

Signal inversion at switch S1. The switching elements are shown under zero-voltage conditions.

B

A 1

24 V

S1

2 3

K1

4

K1

1

24 V 1

S1

2

2 1

K1

2

K1

Y1

0V

3 4

Y1

0V S1

K1

Y1

S1

K1

Y1

0

0

1

0

1

1

1

1

0

1

0

0

© Festo Didactic GmbH & Co. • Electrohydraulics

Signal inversion A 24 V

B

1

S1

2 3

K1

4

K1

1

1

S1

2

Y1

2 1

K1

2

K1

0V

3 4

Y1

0V S1

© Festo Didactic GmbH & Co.

24 V

K1

Y1

S1

0

0

1

1

K1

Y1

TP 601, Transparency 19

20

Latching Latching only with indirect activation. Actuation of switch S1: Relay K1 reverses holding the current path of K1 closed. The actuation of switch S2 interrupts the latched current path.

1

24 V

S1

2 3 4

K1

S2

K1

3 3

K1

4 1 2

Y1

3 4

S1

S2

K1 & Y1

0

0

0

0

1

0

1

0

1

1

1

1

dominant on

0V

© Festo Didactic GmbH & Co. • Electrohydraulics

Latching 24 V

1

S1

2 3 4

K1

S2

K1

3 3

K1

4 1 2

3

S1

S2

4

0

0

0

1

1

0

1

1

K1 & Y1

Y1

0V

© Festo Didactic GmbH & Co.

TP 601, Transparency 20

21

Circuit diagram Lines of potential with constant voltage are drawn horizontally. Current paths are drawn vertically and numbered consecutively. Circuit symbols are shown in the direction of current flow. Switching elements are generally shown under zero-voltage conditions. Latching to guard against sticking of relay contacts in current paths 6 and 7.

24 V

S0

1 3 4

2

S1

3 3 4

K1

4 3 4

S2

5 3 4

K2

6 3 4

K1

K2

K1

A1 A2

K2

A1 A2

Y1

7 3

K2

4 1 2

K1

3 4 1 2

Y2

0V

© Festo Didactic GmbH & Co. • Electrohydraulics

Circuit diagram

S0

3 4

S1

3 4

K1

3 4

S2

3 4

K2

3 4

K1

K2

K1

© Festo Didactic GmbH & Co.

A1 A2

K2

A1 A2

Y1

3

K2

4 1 2

K1

3 4 1 2

Y2

TP 601, Transparency 21

22

Hydraulic power pack Hydraulic power pack for use in stationary hydraulic systems. Power is delivered via the pressure medium using a pump and drive motor. The pack incorporates devices to remove air, water and solid particles from the hydraulic fluid.

Pressure relief valve (safety valve) Pressure line Electric motor n = 1500 rpm

Return line

Hydraulic pump

Suction pipe

Air filter

Suction filter

Fluid level indicator

Filler filter Cleaning aperture

Baffle plate Drain screw

© Festo Didactic GmbH & Co. • Electrohydraulics

Hydraulic power pack

© Festo Didactic GmbH & Co.

TP 601, Transparency 22

23

Hydraulic circuit Hydraulic systems consist of open or closed circuits. Hydraulic fluid is used as an energy carrier. This energy is output via cylinders and motors. Relieved hydraulic fluid is returned to the tank or hydraulic pump.

Hydraulic cylinder

Electrohydraulic power valve

Hydraulic pump

Motor

Return line

Safety valve

Hydraulic pump open

Hydraulic motor

Motor Filter

Safety valve

Feed pump (top-up for leakage losses)

Safety valve

closed

© Festo Didactic GmbH & Co. • Electrohydraulics

Hydraulic circuit

open © Festo Didactic GmbH & Co.

closed TP 601, Transparency 23

24

Electrical power – hydraulic power Electric motor

Driven by electric current on the basis of a potential difference. Electrical power is the product of voltage and current Pelectr. = V • I (unit: watts).

Driven via fluid flow on the basis of a pressure difference. Hydraulic power is the product of pressure and flow rate Phydr. = p • Q (unit: watts).

Pelectr. = V • I

Phydr. = p • q Flow rate q

+

Pressure p

Current I

Voltage V

Hydraulic motor

Electric motor Gear motor

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical power

Hydraulic power

+ -

© Festo Didactic GmbH & Co.

TP 601, Transparency 24

25

Power losses Efficiency of electric motors

· Frictional losses · Magnetic losses

Efficiency of hydraulic pump · Frictional losses · Volumetric losses Valves, piping, tubing

· Pressure losses dp · Power losses expressed by P = dp • Q

Hydraulic motors and cylinders

· Frictional losses · Volumetric losses

Frictional and pressure losses

Power losses

Frictional and volumetric losses

Frictional, volumetric and magnetic losses

Phydr. loss = ,p • q

© Festo Didactic GmbH & Co. • Electrohydraulics

Power losses

© Festo Didactic GmbH & Co.

TP 601, Transparency 25

26

Pressure switches Actuation of electrical contacts when a defined minimum pressure is reached. The minimum pressure (switching point) can be varied by means of an adjustable spring. Example shows switching at approx. 4 bar with rising or falling pressure. Generally connected up in practice as a changeover contact.

2 3

Symbolic representation in hydraulic circuit diagram

p

Symbolic representation in electrical circuit diagram

p 1

1 3 2

Pressure p

4 bar

a

c b

Hysteresis

Time t a/c Switching point with rising pressure b Switching point with falling pressure

© Festo Didactic GmbH & Co. • Electrohydraulics

Pressure switches 2 3

p

p 1

1 3 2

Pressure p 4 bar

Time t

© Festo Didactic GmbH & Co.

TP 601, Transparency 26

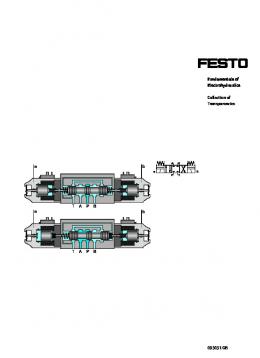

27

4/3-way solenoid valve Valve spool is directly actuated by solenoids. Actuation on left

The piston spool is displaced to the right and creates the connections P – A and B – T.

Rest position

Rest position produced by spring centring of piston spool. All inputs of the 4/3-way valve are closed in this position.

a

b a

a

T

A

P

B

T

A

P

B

A

B

P

T

b

b

© Festo Didactic GmbH & Co. • Electrohydraulics

4/3-way solenoid valve

a

© Festo Didactic GmbH & Co.

T

A

P

B

T

A

P

B

A

B

P

T

b

TP 601, Transparency 27

28

4/3-way solenoid valve, piloted Direct activation of pilot spool via solenoids. Actuation on left

The pilot piston spool is displaced to the right, and hydraulic fluid is directed to the right-hand side of the main control spool, creating the connections P – A and B – T.

Rest position

Rest position produced by spring centring of pilot and main piston spools. All ports of the 4/3-way valve are closed at the main valve.

A

B

P

T

Simplified symbol

T

B

P

A

A

B

P

T

Detailed symbol

© Festo Didactic GmbH & Co. • Electrohydraulics

4/3-way solenoid valve, piloted

T © Festo Didactic GmbH & Co.

B

P

A

A

B

P

T

A

B

P

T

TP 601, Transparency 28

29

Electrical safety

· · · · ·

EMERGENCY STOP button placed in an easily accessible position Protection against voltages Protection by means of insulation Protection by means of earthed conductive housings Safety isolation by means of transformers

1) Switch off 2) Check 3) Carry out work EMERGENCY STOP Safety insulation

Protective earth

Safety isolation

Additional insulation L1 PE

220 V AC

24 V

N

Basic insulation

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical safety

Safety insulation

© Festo Didactic GmbH & Co.

Protective earth

Safety isolation

TP 601, Transparency 29

30

Hydraulic safety Safety regulations must be observed.

· · · ·

Switch off motor/pump Depressurise accumulator Lower load Check pressure

Work can now be carried out by authorised trained personnel.

m

1) Switch off motor/pump

2) Depressurise accumulator

3) Lower load

4) Check pressure

© Festo Didactic GmbH & Co. • Electrohydraulics

Hydraulic safety

m

© Festo Didactic GmbH & Co.

TP 601, Transparency 30

a

b a

a

T

A

P

B

T

A

P

B

A

B

P

T

b

b

095051 GB

Order no.: Designation: Description: Edition: Author: Graphics: Layout:

095051 E.-HYDR-FOLIEN. D:OT-TP601-GB 07/2001 Dieter Scholz Doris Schwarzenberger 18.07.2001, Beatrice Huber

© Festo Didactic GmbH & Co., D-73770 Denkendorf, 2001 Internet: www.festo.com/didactic e-mail: [email protected] The copying, distribution and utilization of this document as well as the communication of its contents to others without expressed authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved, in particular the right to carry out patent, utility model or ornamental design registration.

Foreword

This set of overhead transparencies has been designed for use with the basic level of the technology package TP600 “Electrohydraulics”. The set of overhead transparencies and the technology package form part of the Learning System for Automation from Festo Didactic GmbH & Co. The 30 transparencies in this set have been optimised from the didactic and methodological points of view. Each transparency is accompanied by a short text which provides the trainer with a quick overview of the training contents of the transparency concerned. Training contents

· · · ·

Basic principles of electrohydraulics Function and use of electrohydraulic components Basic principles of electrical engineering Production and interpretation of standard hydraulic and electrical circuit diagrams

The text sheet includes a complete illustration of the transparency, in certain cases with additional explanations and legends which the trainer can enter on the transparency in the course of a training session. The advantages of this concept are: · The trainer can add to the transparencies step by step in the course of a training session. · The trainer is thus able to create a lively and interesting atmosphere. · The provision of accompanying text means less preparation work for the trainer. New! Electronic presentation

The enclosed CD-ROM contains the entire overhead transparencies and accompanying text of this edition in an electronically presentable form in the files „Electrohydraulics _transparencies.pdf“ and „Electrohydraulics _text.pdf“. In addition to the screen presentation, which can be made in any order, the contents can be printed out and text and graphics can be used for your own training ® ® preparations, insofar as the functionality of the required Adobe Acrobat Reader permits this. This freely distributable software is available on the CD-ROM in the currently valid English version for Windows 95/98/NT for installation in the directory „Acrobat_Reader“. Please start the file „rs405eng.exe“ and follow the subsequent dialogue.

© Festo Didactic GmbH & Co. • Electrohydraulics

Contents

Electrohydraulic press _______________________________________ Transparency 1 Schematic layout of an electrohydraulic installation ______________ Transparency 2 Electrical power supply unit __________________________________ Transparency 3 Electrical circuit ____________________________________________ Transparency 4 Measuring circuits __________________________________________ Transparency 5 Ohm’s law _________________________________________________ Transparency 6 Rectifiers __________________________________________________ Transparency 7 Analogue, digital and binary __________________________________ Transparency 8 Momentary and sustained contact switches _____________________ Transparency 9 N/O, N/C and changeover contacts ___________________________ Transparency 10 Limit switches _____________________________________________ Transparency 11 Proximity switches _________________________________________ Transparency 12 Solenoid (electromagnet) ___________________________________ Transparency 13 Electrohydraulic converters (solenoid valves)___________________ Transparency 14 Dry solenoids – wet solenoids________________________________ Transparency 15 Solenoid valve connections__________________________________ Transparency 16 Relays and contactors ______________________________________ Transparency 17 Direct activation – indirect activation __________________________ Transparency 18 Signal inversion ___________________________________________ Transparency 19 Latching__________________________________________________ Transparency 20 Circuit diagram ____________________________________________ Transparency 21 Hydraulic power pack_______________________________________ Transparency 22 Hydraulic circuit ___________________________________________ Transparency 23 Electrical power – hydraulic power ____________________________ Transparency 24 Power losses______________________________________________ Transparency 25 Pressure switches__________________________________________ Transparency 26 4/3-way solenoid valve _____________________________________ Transparency 27 4/3-way solenoid valve, piloted ______________________________ Transparency 28 Electrical safety____________________________________________ Transparency 29 Hydraulic safety ___________________________________________ Transparency 30

© Festo Didactic GmbH & Co. • Electrohydraulics

1

Electrohydraulic press Function units

· · · ·

Motor with hydraulic pump Control panel Valve manifold Cylinder

The hydraulic press is controlled via the electrical control panel. Electrical signals are used to activate the valves in the hydraulic installation. The electrohydraulic press is used to form rectangular troughs.

Motor with hydraulic pump Valve manifold

Actuator (cylinder)

Control pane

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrohydraulic press

© Festo Didactic GmbH & Co.

TP 601, Transparency 01

2

Schematic layout of an electrohydraulic installation Division of installation into signal control section and hydraulic power section. Signal control section

Input and processing of electrical signals. Solenoid valves form the interface between the electrical signal control section and the hydraulic power section. Controls the flow of hydraulic fluid by means of solenoid valves. Actuators convert hydraulic energy into motions.

Power section Signal control section

Hydraulic cylinder

Signal processing

Signal input

è

Solenoid valve

è

è

è è Power supply

è

Hydraulic power section

Hydraulic power supply (conversion)

© Festo Didactic GmbH & Co. • Electrohydraulics

Schematic layout of an electrohydraulic installation Power section Signal control section

è

è

è

è

è

è

© Festo Didactic GmbH & Co.

TP 601, Transparency 02

3

Electrical power supply unit Connection to mains supply. Supplies signal control section with specified or maximum voltage and current values. Functions in power supply unit

· · · · ·

Voltage transformation Rectification Smoothing Stabilisation Fuse protection

In mobile hydraulic systems, rechargeable battery systems or generators are used as a power supply for the signal control section.

230V AC DC 24V

50 °C

TR

G

Transformer

Rectifier

C

T

T

Smoothing Stabilisation

Fuse

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical power supply unit 230V AC DC 24V

TR © Festo Didactic GmbH & Co.

G

C

T

T TP 601, Transparency 03

4

Electrical circuit A circuit consists of at least a power source, a load device and connecting lines. Electrical current will flow only in a closed circuit. Technical direction of current flow

Electrical current flows from the positive terminal of the power supply to the negative terminal.

Figure A

Closed circuit without power supply.

Figure B

Introduction of a power supply to complete the circuit.

A

B

+

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical circuit A

© Festo Didactic GmbH & Co.

B

TP 601, Transparency 04

5

Measuring circuits Voltage measurement

The voltage drop across a load device is measured in parallel with the device.

Current measurement

Electrical current is measured in series.

+

+

Voltage measurement

Current measurement

© Festo Didactic GmbH & Co. • Electrohydraulics

Measuring circuits

+

+

-

-

© Festo Didactic GmbH & Co.

TP 601, Transparency 05

6

Ohm’s law Ohm’s law

Describes the relationship between current (I), voltage (V) and resistance (R). With ohmic resistances, the current rises in linear proportion to the voltage. The value pairs for a constant resistance lie on a straight line. The current I is proportional to the voltage V. Mathematical formula for Ohm’s law:

V=R•I

I=

+

V=R•I I=V:R

Resistance R

Voltage V 10 V 20 V

30 V

40 V

Relay

0.5 A

1.5 A

2.0 A

Solenoid coil

0.33 A 0.66 A 1.0 A

V R

1.33 A

2.0 A 1.5

A R

1.0 A

1.0

V

I

Graph

0.5 0

0

10

20

30 V 40

V

© Festo Didactic GmbH & Co. • Electrohydraulics

Ohm’s law Voltage V 10 V 20 V

Resistance R

30 V

40 V

Relay Solenoid coil

-

A

R

V

1.0

I

+

2.0 A 1.5

0.5 0

0

10

20

30 V 40

V © Festo Didactic GmbH & Co.

TP 601, Transparency 06

7

Rectifiers Rectifiers convert AC to DC. Diodes are conductive in only one direction. The polarity of the negative half-wave of the alternating voltage is reversed. The pulsating voltage is smoothed using a capacitor and filters (reactance coil, resistor).

L

~ C

Diodes

t

=

V

Voltage smoothing

V

V

Voltage retification

R

t

t

© Festo Didactic GmbH & Co. • Electrohydraulics

Rectifiers ~

t © Festo Didactic GmbH & Co.

V

V

V

=

t

t TP 601, Transparency 07

8

Analogue, digital and binary Analogue values

Analogue values describe continuous functions, such as the continuous filling of a bucket of water.

Digital values

Digital values describe integer parts of a maximum value. A dice, for example, shows one of six possible numbers.

Binary values

Binary values are a special form of digital values. They can assume only two values, such as in the case of a switch, which can only be on or off.

halffull empty

Filling time t

6 5 4 3 2 1 0

On 1

Light

full

Value

Volume V

+

Experiments with dice

Off 0

Switching time point

Time t

© Festo Didactic GmbH & Co. • Electrohydraulics

Analogue, digital and binary

+

Filling time t © Festo Didactic GmbH & Co.

Light

Value

Volume V

-

Experiments with dice

Time t TP 601, Transparency 08

9

Momentary and sustained contact switches Actuation of contacts. Momentary contact switch

A momentary contact switch has a “rest position” and an “actuated position”.

Sustained contact switch

A sustained contact switch has two detents. It thus has two rest positions. Momentary and sustained switches can close or open current paths or switch from one current path to another.

3

3

4

4

© Festo Didactic GmbH & Co. • Electrohydraulics

Momentary and sustained contact switches

© Festo Didactic GmbH & Co.

TP 601, Transparency 09

10

N/O, N/C and changeover contacts N/O

Contact normally open in rest position.

N/C

Example: Momentary-contact switch

Changeover contact

N/O and N/C contacts in a single housing; one contact is open while the other is closed. The designations of the switch contacts are governed by the European standard EN 50012.

Switch elements Connection (N/O contact)

3 4

1 2

2

4

Connection (N/C contact)

1

© Festo Didactic GmbH & Co. • Electrohydraulics

N/O, N/C and changeover contacts

© Festo Didactic GmbH & Co.

TP 601, Transparency 10

11

Limit switches Determining the position of a positioning slide. Electrical contacts are actuated when a defined intermediate or end position is reached. Limit switches can be connected up as N/O, N/C or changeover contacts.

Switch lever Stem (insulated)

Contact

Snap-action mechanism

© Festo Didactic GmbH & Co. • Electrohydraulics

Limit switches

© Festo Didactic GmbH & Co.

TP 601, Transparency 11

12

Proximity switches Inductive

Signal is generated by the presence of any material with good conductivity in an oscillating magnetic field.

Capacitive

Signal is also generated by all insulators with high dielectric constants in an electrical field.

Optical

Signal is generated when light barriers are interrupted or when light is reflected back to an optical sensor.

Reed switches

Signal is generated by magnets whose fields close the built-in contacts in the switch.

inductive

Metal

Reed switch

Magnet capacitive

Metal or Insulator

optical

reflective component

magnetic

© Festo Didactic GmbH & Co. • Electrohydraulics

Proximity switches

© Festo Didactic GmbH & Co.

TP 601, Transparency 12

13

Solenoid (electromagnet) A magnetic field with concentric field lines is created around a conductor carrying an electrical current. A coil carrying an electrical current develops a uniform magnetic field in its axial direction due to the overlapping of field lines. By appropriate alignment of elementary magnets, an iron core can be made into a switchable electromagnet.

Field around a conductor

Iron core

+

Coil Coil

© Festo Didactic GmbH & Co. • Electrohydraulics

Solenoid (electromagnet)

+ -

© Festo Didactic GmbH & Co.

TP 601, Transparency 13

14

Electrohydraulic converters (solenoid valves) Convert electrical signals into hydraulic switching operations. The switching armature is drawn into the coil, which acts as a magnet. This produces a displacement of the actuating piston in the hydraulic 4/2-way valve.

Switching armature

A

B

P

T

4/2-way solenoid valve

T

A

P

B

L

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrohydraulic converters (solenoid valves)

© Festo Didactic GmbH & Co.

A

B

P

T

TP 601, Transparency 14

15

Dry solenoids – wet solenoids Dry solenoid

The solenoid is separated from the hydraulic fluid; a seal is required on the stem.

Advantage

· Simple construction

Wet solenoid

The armature chamber of the solenoid is filled with hydraulic fluid, the solenoid operates in oil.

Advantages

· · · ·

Low friction Little abrasion Good heat dissipation Long service life

seal

Dry solenoid

Wet solenoid

© Festo Didactic GmbH & Co. • Electrohydraulics

Dry solenoid

© Festo Didactic GmbH & Co.

Wet solenoid

TP 601, Transparency 15

16

Solenoid valve connections Connector components

· Solenoid with plug base · Cable with connector socket Electrical signals are transmitted via standard connectors.

Advantages

· Reliable alignment of connections · Connections can be attached and detached quickly · Protected against dust and water

2 3 1

Electrical connections

Protective earth connection Plug base

© Festo Didactic GmbH & Co. • Electrohydraulics

Solenoid valve connections 2 3 1

© Festo Didactic GmbH & Co.

TP 601, Transparency 16

17

Relays and contactors Definition

Switches which are actuated and held in their actuated positions electromagnetically. Used to separate control and power circuits.

Special feature of relays

· · · ·

Special feature of contactors

Each main contact is of double-break type (contacts used as main contacts), suitable for · all power ratings from small to very large · only N/O and N/C contacts

Hinged-armature design Single-break contacts Used for logic gating of signals (generally) changeover contacts

Coil

Iron core Armature

Return spring Contacts

+ +

Contacts Return spring Hinged-armature solenoid

Coil Plunger-armature solenoid

© Festo Didactic GmbH & Co. • Electrohydraulics

Relays and contactors

+ -

+ -

© Festo Didactic GmbH & Co.

TP 601, Transparency 17

18

Direct activation – indirect activation Direct activation

Connection of a solenoid valve via a switch (Fig. A).

Indirect activation

Connection of a solenoid valve via a relay (Fig. B).

Advantage of indirect activation

· Separation of control and power circuits · The current passing through switch S1 (Fig. B) is lower, and the service life of the switch is significantly greater.

A

B

1

24 V

S1

3

S1

4

Y1 0V

1

24 V

K1

2

3 4

K1

3 4

Y1

0V

© Festo Didactic GmbH & Co. • Electrohydraulics

Direct activation

24 V

0V

© Festo Didactic GmbH & Co.

1

Indirect activation

24 V

1

2

0V

TP 601, Transparency 18

19

Signal inversion The output signal is inversely proportional to the input signal. Figure A

Signal inversion at relay K1.

Figure B

Signal inversion at switch S1. The switching elements are shown under zero-voltage conditions.

B

A 1

24 V

S1

2 3

K1

4

K1

1

24 V 1

S1

2

2 1

K1

2

K1

Y1

0V

3 4

Y1

0V S1

K1

Y1

S1

K1

Y1

0

0

1

0

1

1

1

1

0

1

0

0

© Festo Didactic GmbH & Co. • Electrohydraulics

Signal inversion A 24 V

B

1

S1

2 3

K1

4

K1

1

1

S1

2

Y1

2 1

K1

2

K1

0V

3 4

Y1

0V S1

© Festo Didactic GmbH & Co.

24 V

K1

Y1

S1

0

0

1

1

K1

Y1

TP 601, Transparency 19

20

Latching Latching only with indirect activation. Actuation of switch S1: Relay K1 reverses holding the current path of K1 closed. The actuation of switch S2 interrupts the latched current path.

1

24 V

S1

2 3 4

K1

S2

K1

3 3

K1

4 1 2

Y1

3 4

S1

S2

K1 & Y1

0

0

0

0

1

0

1

0

1

1

1

1

dominant on

0V

© Festo Didactic GmbH & Co. • Electrohydraulics

Latching 24 V

1

S1

2 3 4

K1

S2

K1

3 3

K1

4 1 2

3

S1

S2

4

0

0

0

1

1

0

1

1

K1 & Y1

Y1

0V

© Festo Didactic GmbH & Co.

TP 601, Transparency 20

21

Circuit diagram Lines of potential with constant voltage are drawn horizontally. Current paths are drawn vertically and numbered consecutively. Circuit symbols are shown in the direction of current flow. Switching elements are generally shown under zero-voltage conditions. Latching to guard against sticking of relay contacts in current paths 6 and 7.

24 V

S0

1 3 4

2

S1

3 3 4

K1

4 3 4

S2

5 3 4

K2

6 3 4

K1

K2

K1

A1 A2

K2

A1 A2

Y1

7 3

K2

4 1 2

K1

3 4 1 2

Y2

0V

© Festo Didactic GmbH & Co. • Electrohydraulics

Circuit diagram

S0

3 4

S1

3 4

K1

3 4

S2

3 4

K2

3 4

K1

K2

K1

© Festo Didactic GmbH & Co.

A1 A2

K2

A1 A2

Y1

3

K2

4 1 2

K1

3 4 1 2

Y2

TP 601, Transparency 21

22

Hydraulic power pack Hydraulic power pack for use in stationary hydraulic systems. Power is delivered via the pressure medium using a pump and drive motor. The pack incorporates devices to remove air, water and solid particles from the hydraulic fluid.

Pressure relief valve (safety valve) Pressure line Electric motor n = 1500 rpm

Return line

Hydraulic pump

Suction pipe

Air filter

Suction filter

Fluid level indicator

Filler filter Cleaning aperture

Baffle plate Drain screw

© Festo Didactic GmbH & Co. • Electrohydraulics

Hydraulic power pack

© Festo Didactic GmbH & Co.

TP 601, Transparency 22

23

Hydraulic circuit Hydraulic systems consist of open or closed circuits. Hydraulic fluid is used as an energy carrier. This energy is output via cylinders and motors. Relieved hydraulic fluid is returned to the tank or hydraulic pump.

Hydraulic cylinder

Electrohydraulic power valve

Hydraulic pump

Motor

Return line

Safety valve

Hydraulic pump open

Hydraulic motor

Motor Filter

Safety valve

Feed pump (top-up for leakage losses)

Safety valve

closed

© Festo Didactic GmbH & Co. • Electrohydraulics

Hydraulic circuit

open © Festo Didactic GmbH & Co.

closed TP 601, Transparency 23

24

Electrical power – hydraulic power Electric motor

Driven by electric current on the basis of a potential difference. Electrical power is the product of voltage and current Pelectr. = V • I (unit: watts).

Driven via fluid flow on the basis of a pressure difference. Hydraulic power is the product of pressure and flow rate Phydr. = p • Q (unit: watts).

Pelectr. = V • I

Phydr. = p • q Flow rate q

+

Pressure p

Current I

Voltage V

Hydraulic motor

Electric motor Gear motor

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical power

Hydraulic power

+ -

© Festo Didactic GmbH & Co.

TP 601, Transparency 24

25

Power losses Efficiency of electric motors

· Frictional losses · Magnetic losses

Efficiency of hydraulic pump · Frictional losses · Volumetric losses Valves, piping, tubing

· Pressure losses dp · Power losses expressed by P = dp • Q

Hydraulic motors and cylinders

· Frictional losses · Volumetric losses

Frictional and pressure losses

Power losses

Frictional and volumetric losses

Frictional, volumetric and magnetic losses

Phydr. loss = ,p • q

© Festo Didactic GmbH & Co. • Electrohydraulics

Power losses

© Festo Didactic GmbH & Co.

TP 601, Transparency 25

26

Pressure switches Actuation of electrical contacts when a defined minimum pressure is reached. The minimum pressure (switching point) can be varied by means of an adjustable spring. Example shows switching at approx. 4 bar with rising or falling pressure. Generally connected up in practice as a changeover contact.

2 3

Symbolic representation in hydraulic circuit diagram

p

Symbolic representation in electrical circuit diagram

p 1

1 3 2

Pressure p

4 bar

a

c b

Hysteresis

Time t a/c Switching point with rising pressure b Switching point with falling pressure

© Festo Didactic GmbH & Co. • Electrohydraulics

Pressure switches 2 3

p

p 1

1 3 2

Pressure p 4 bar

Time t

© Festo Didactic GmbH & Co.

TP 601, Transparency 26

27

4/3-way solenoid valve Valve spool is directly actuated by solenoids. Actuation on left

The piston spool is displaced to the right and creates the connections P – A and B – T.

Rest position

Rest position produced by spring centring of piston spool. All inputs of the 4/3-way valve are closed in this position.

a

b a

a

T

A

P

B

T

A

P

B

A

B

P

T

b

b

© Festo Didactic GmbH & Co. • Electrohydraulics

4/3-way solenoid valve

a

© Festo Didactic GmbH & Co.

T

A

P

B

T

A

P

B

A

B

P

T

b

TP 601, Transparency 27

28

4/3-way solenoid valve, piloted Direct activation of pilot spool via solenoids. Actuation on left

The pilot piston spool is displaced to the right, and hydraulic fluid is directed to the right-hand side of the main control spool, creating the connections P – A and B – T.

Rest position

Rest position produced by spring centring of pilot and main piston spools. All ports of the 4/3-way valve are closed at the main valve.

A

B

P

T

Simplified symbol

T

B

P

A

A

B

P

T

Detailed symbol

© Festo Didactic GmbH & Co. • Electrohydraulics

4/3-way solenoid valve, piloted

T © Festo Didactic GmbH & Co.

B

P

A

A

B

P

T

A

B

P

T

TP 601, Transparency 28

29

Electrical safety

· · · · ·

EMERGENCY STOP button placed in an easily accessible position Protection against voltages Protection by means of insulation Protection by means of earthed conductive housings Safety isolation by means of transformers

1) Switch off 2) Check 3) Carry out work EMERGENCY STOP Safety insulation

Protective earth

Safety isolation

Additional insulation L1 PE

220 V AC

24 V

N

Basic insulation

© Festo Didactic GmbH & Co. • Electrohydraulics

Electrical safety

Safety insulation

© Festo Didactic GmbH & Co.

Protective earth

Safety isolation

TP 601, Transparency 29

30

Hydraulic safety Safety regulations must be observed.

· · · ·

Switch off motor/pump Depressurise accumulator Lower load Check pressure

Work can now be carried out by authorised trained personnel.

m

1) Switch off motor/pump

2) Depressurise accumulator

3) Lower load

4) Check pressure

© Festo Didactic GmbH & Co. • Electrohydraulics

Hydraulic safety

m

© Festo Didactic GmbH & Co.

TP 601, Transparency 30

Related documents

TRANSPARENCIES ELECTROHYDRAULICS FESTO

64 Pages • 3,669 Words • PDF • 7.6 MB

FESTO Manual bancada pneumatica 06-08

172 Pages • 28,111 Words • PDF • 3.7 MB